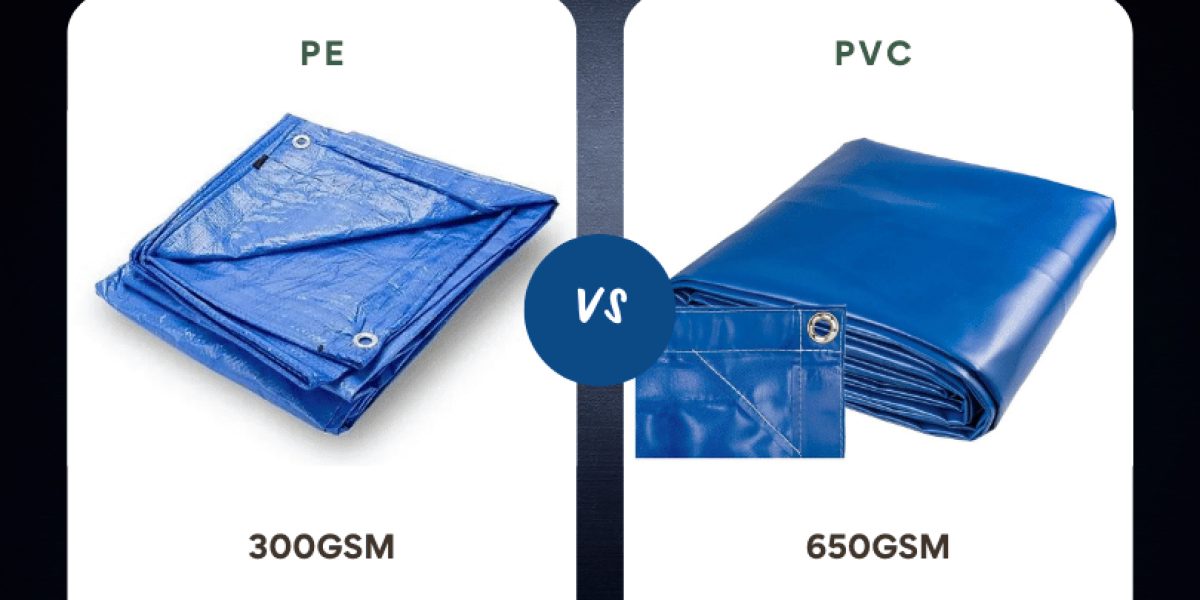

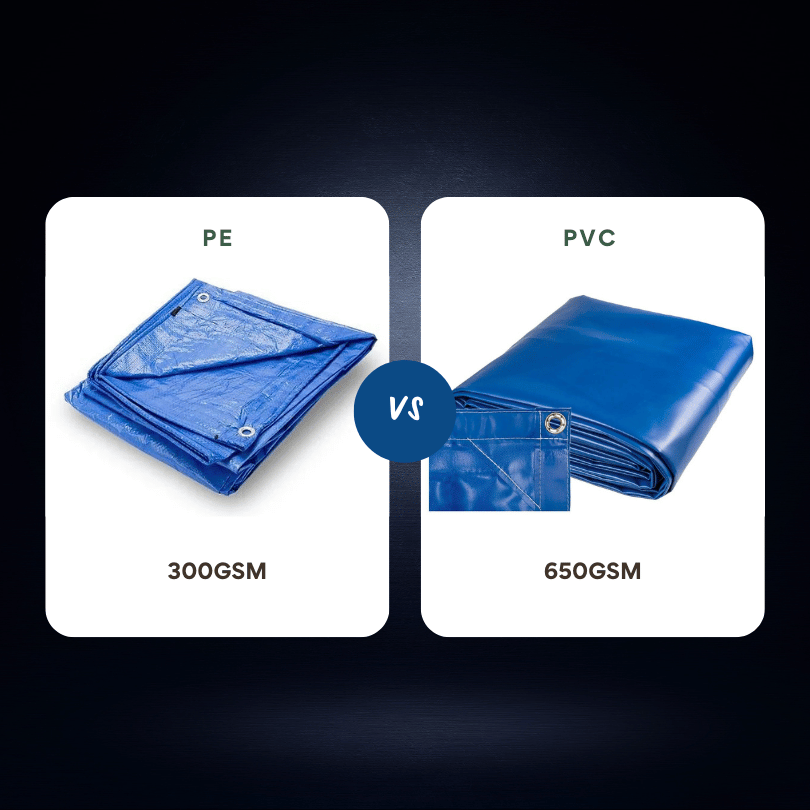

PE vs PVC 650 Canvas: The main differences

When it comes to selecting the right canvas for outdoor projects, tarps, or shelters, the choice often boils down to two popular materials: PE (Polyethylene) and PVC (Polyvinyl Chloride) 650 canvas. Both materials are known for their durability and protective qualities, but they have distinct characteristics that make them suitable for different applications. Let’s unravel the differences between PE and PVC 650 canvas to help you make an informed decision for your next project.

What is PE Canvas?

PE canvas is made from polyethylene, a lightweight, flexible plastic. PE canvases are known for their:

Water Resistance: PE is naturally waterproof, making it a top pick for outdoor covers and tarps.

UV Protection: It offers excellent resistance to sun damage, which is essential for long-term outdoor use.

Affordability: Generally, PE canvas is a cost-effective option for those on a budget.

Ideal Uses for PE Canvas: Due to its properties, PE canvas is often used for making everyday items like lightweight outdoor covers, disposable tarps, or temporary shelters.

What is PVC 650 Canvas?

PVC 650 canvas refers to a heavier-duty canvas made from polyvinyl chloride that has a weight of 650 grams per square meter. This type of canvas boasts:

Superior Strength: PVC 650 canvas is known for its toughness, making it suitable for heavy-duty use.

Chemical Resistance: It stands up well against a variety of chemicals, oils, and acids.

Longevity: PVC canvas typically has a longer lifespan due to its robust nature.

Ideal Uses for PVC 650 Canvas: It’s used for industrial purposes, such as truck covers, heavy-duty tarps, high-stress outdoor tents and high tunnel greenhouse.

Comparing PE and PVC 650 Canvas

1. Durability: While both materials are durable, PVC 650 canvas outperforms PE in terms of tear resistance and longevity, especially in harsh environmental conditions.

2. Weight: PE canvas is lighter, which may be beneficial for applications where the canvas needs to be moved frequently. In contrast, PVC 650 is heavier, which contributes to its durability and stability in high-wind situations.

3. Flexibility: PE canvas is more flexible at lower temperatures compared to PVC, which can become stiff in cold weather. However, PVC can maintain its structural integrity better under mechanical stress.

4. Environmental Impact: PE is less environmentally impactful to produce than PVC, which releases more dioxins during manufacture. However, PVC often lasts longer, potentially reducing waste over time.

5. Price Point: PE canvas is the more cost-effective option upfront, but the extended durability of PVC 650 canvas can offer better value over its lifespan.

If you want a good project with PVC you can see the products we have for you And many discounts with limited offer as modular office.

Conclusion

The decision between PE and PVC 650 canvas ultimately depends on the specific requirements of your project. For light, temporary, or cost-sensitive applications, PE canvas is a suitable choice. However, for projects that demand the utmost in strength, durability, and resistance to elements, PVC 650 canvas is the clear winner.

Before making your final decision, consider the longevity, conditions of use, environmental factors, and budget. By assessing these factors, you’ll be able to choose the right material that stands up to the task and offers the best return on investment for your needs.