Advantages and disadvantages of quonset hut buildings

What is a quonset hut?

Quonset hut buildings are prefabricated structures often used in industrial settings. Their corrugated steel walls and roof make them extremely durable and weather-resistant.

Quonset hut buildings are also surprisingly easy to assemble, making them ideal as a DIY project. Despite these benefits, many believe quonset hut buildings por-quality due to its base and design.

We asure that our Quonset hut buildings are not inferior but rather a valuable resource for those who what to save time and money.

The main advantages of having a quonset hut is that they are re-buildable.

This means that it can be used in remote locations where traditional building designs are not convenient.

Construction workers don’t need specialized training or equipment to build a quonset hut. They can also easily modify its size and shape to suit your needs.It’s design can be easily modified for different uses.

Is it easy to build?

Quonset hut buildings are a good investment due to the fact that there very easy to setup, They only require basic hardware to build.

Anyone with the proper knowledge can assemble a quonset hut building in a matter of hours. This makes them ideal for people who don’t have time to spare on construction projects.

They can also be easily transported so you can build them wherever you like. These qualities make quonset hut buildings an excellent choice for people on a budget.

How much does a quonset hut cost?

The cost of a Quonset hut can vary widely depending on several factors, including the size, style, and features of the building, as well as your location and the cost of materials and labor in your area.

As a rough estimate, a basic Quonset hut kit without any customization can cost between $5,000 and $15,000 for a smaller size, while larger or more complex structures can cost upwards of $50,000 or more.

However, keep in mind that these prices do not include any additional costs for site preparation, foundation, installation, or customization, which can add significant costs to the overall project.

It’s best to consult with a Quonset hut manufacturer or contractor for a more accurate estimate based on your specific needs and requirements.

Each consumer must weigh the pros and cons of investing in quonset hut building kits before making their final decision since they’re an excellent option when putting some things aside depending on what you plan on doing with them once you’ve purchased them.

it’s important to keep an eye on their condition and keep them in shape so you don’t end up wasting money due to poor quality care. when trying to save money in other areas such as transportation costs just considering how easily they can be transported compared to traditional buildings with heavier materials.

So as long as you plan accordingly beforehand you won’t have headaches down the line from unexpected expenses from repair costs since investing in products like this and saving upfront does work long term especially with good quality products like this one.

Is there any alternative?

For most people, fabric building is usually more cost-effective. Since they are resistant structures and even more at a lower cost.

Their maintenance is cheaper than a Quonset hut but it is important to take into account the thickness of the canvas.

Our prefabricated buildings offer an open-span design that can be assembled in less time than traditional buildings and can be easily relocated.

Unlike wood-built construction, steel buildings, concrete, tilt-slab buildings or brick-and-mortar structures, our custom build structures have minimal foundation requirements and drastically reduce construction schedules.

The fabric tent systems we sell are designed for rapid setup with minimal labor, equipment, and tool requirements. Our tensioned fabric buildings are engineered to meet local and international building codes for safety

-

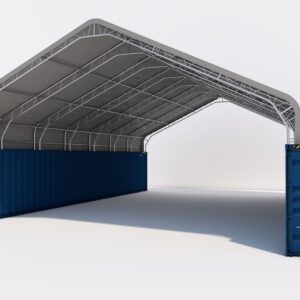

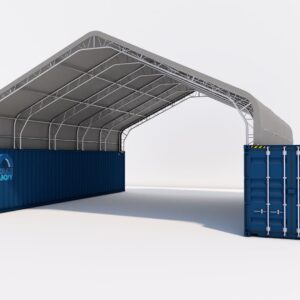

Shipping Container Sheds

Shipping Container Sheds

26W-40L- 10H (ft)

Double Truss$5,720.00 -

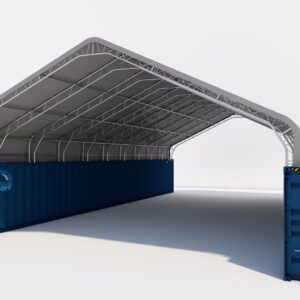

Shipping Container Shed

Shipping Container Shed

20W-40L- 6.5H (ft)

Double Truss$4,399.00 -

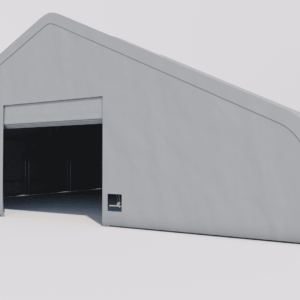

Hoop Barn

Hoop Barn

40W-60L-15H (ft)

Double Truss Peak$9,999.00 -

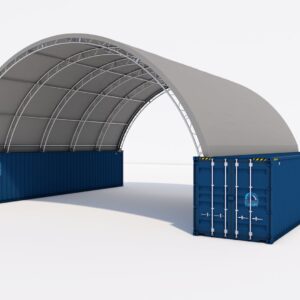

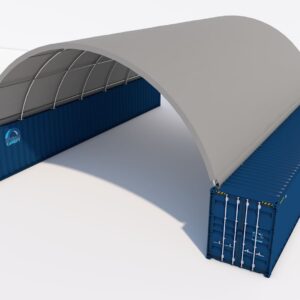

Container Shelter

Container Shelter

40W-40L-15H (ft)

Double Truss Dome$5,850.00 – $5,999.00 -

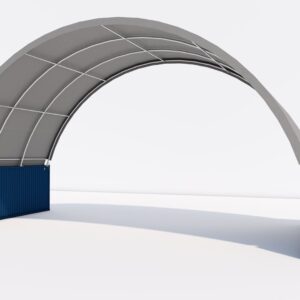

Shipping Container Canopy

Shipping Container Canopy

40W-20L-15H (ft)$3,490.00 -

Kwanzaa Hut

Kwanzaa Hut

33W-40L-10H (ft) Peak Double Truss$5,500.00 -

Hoop Buildings

Hoop Buildings

40W-80L-15H (ft)

Double truss Peak$11,200.00 -

Shipping container roof

Shipping container roof

40W-60L-15H (ft)

Single truss$7,380.00 – $7,420.00 -

Fabric building

Fabric building

70W-200L-28H (ft)$97,812.00

What is their origin and what are they used for?

It was named after the Quonset Point Naval Base. The quonset hut has many advantages when you compare it to a traditional building designs because they are fairly manageable, versatile and portable. However they are suitable for most, but not all environments.

Steel quonset were originally designed for military use during World War II, but today they are used for a variety of purposes in both residential and commercial settings. Here are some common uses for Quonset huts:

- Storage: They make excellent storage facilities for a variety of items, including vehicles, equipment, and supplies.

- Workshops: They are often used as workshops for a variety of trades, including woodworking, metalworking, and automotive repair.

- Agricultural buildings: Quonset huts are ideal for use as agricultural buildings, such as barns, stables, and equipment storage.

- Retail spaces: They can be used as retail spaces, such as shops or restaurants, due to their unique shape and versatility.

- Living spaces: With proper insulation and finishing, they can be used as residential spaces, such as homes or vacation cabins.

- Emergency shelters: They can be used as emergency shelters in disaster-prone areas due to their durability and quick construction.

- Greenhouses: Quonset huts can be modified to create efficient and cost-effective greenhouse structures for growing plants.

These are just a few examples of the many uses for. Their versatility, durability, and ease of construction make them an attractive option for a variety of applications.

How to insulate a quonset hut?

Insulating a arch buildings is important to maintain a comfortable temperature inside the building and to reduce energy costs. Here are some steps you can follow to insulate a Quonset hut:

- Determine the type of insulation: There are several types of insulation materials available such as fiberglass, spray foam, cellulose, and rigid foam. You can consult with an insulation professional to determine which type of insulation is best for your Quonset hut.

- Install a vapor barrier: Before installing insulation, it’s important to install a vapor barrier to prevent moisture from getting into the insulation. A vapor barrier can be made of plastic or other moisture-resistant material.

- Install insulation: Once the vapor barrier is in place, install the insulation material between the ribs of the Quonset hut. It’s important to ensure that the insulation is tightly packed to prevent air gaps.

- Seal gaps and cracks: To further prevent air leakage, seal any gaps or cracks in the Quonset hut with weatherstripping or caulk.

- Install a radiant barrier: A radiant barrier can be installed on top of the insulation to reflect heat and reduce energy costs. This is particularly useful in hot climates.

It’s best to consult with a professional insulation contractor for the best results. They can help you determine the most effective insulation solution for your Quonset hut and ensure that it’s installed properly.

How to build a quonset hut?

Building a Quonset hut requires careful planning and attention to detail. Here are some basic steps to follow when building a Quonset hut:

- Choose a site: The first step in building a Quonset hut is to choose a suitable site. The site should be level and free from any obstructions or obstacles that may interfere with construction.

- Obtain necessary permits: Before beginning construction, it’s important to obtain any necessary permits from your local government or building authority.

- Prepare the site: Clear the site of any vegetation or debris, and level the ground if necessary. Install any necessary drainage or plumbing.

- Assemble the frame: frame consists of arched metal panels that are bolted together. Start by assembling the end arches, and then connect the arches with a ridge beam.

- Install the walls and roof: Once the frame is assembled, install the walls and roof panels. Use screws or bolts to secure the panels to the frame.

- Install windows and doors: Cut openings for windows and doors, and install them according to the manufacturer’s instructions.

- Finish the interior: Insulate the Quonset hut and finish the interior as desired. This may include installing drywall, flooring, and electrical and plumbing systems.

It’s important to follow the manufacturer’s instructions carefully when building a Quonset hut, and to consult with a professional contractor or engineer if you have any questions or concerns.